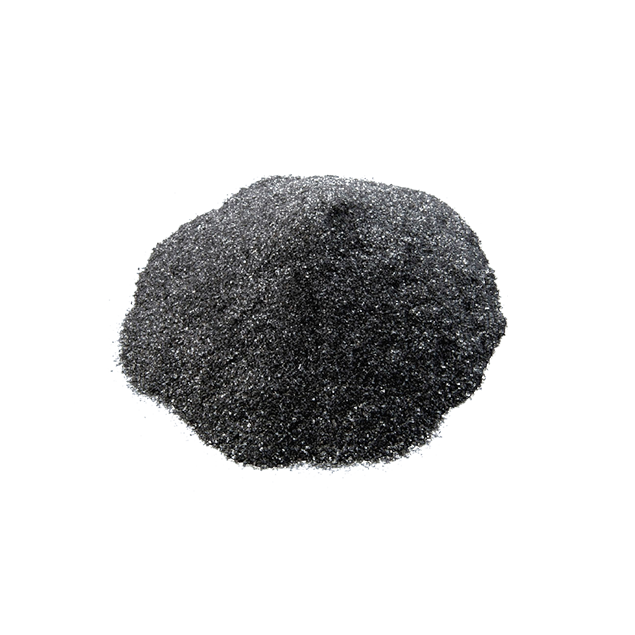

Magnet Powder

Newland magnetic powders are based upon Nd-Fe-B alloy compositions that are quickly solidified from their molten state at high cooling rates. This rapid solidification results in a material that has a precise grain structure. Due to the small grain size, these materials are magnetically isotropic. Unlike the very fine, anisotropic powders that are used to manufacture sintered NdFeB magnets, Newland’s powder is stable against oxidation-forced demagnetization. This makes Newland powders easily ready for making bonded permanent magnets.

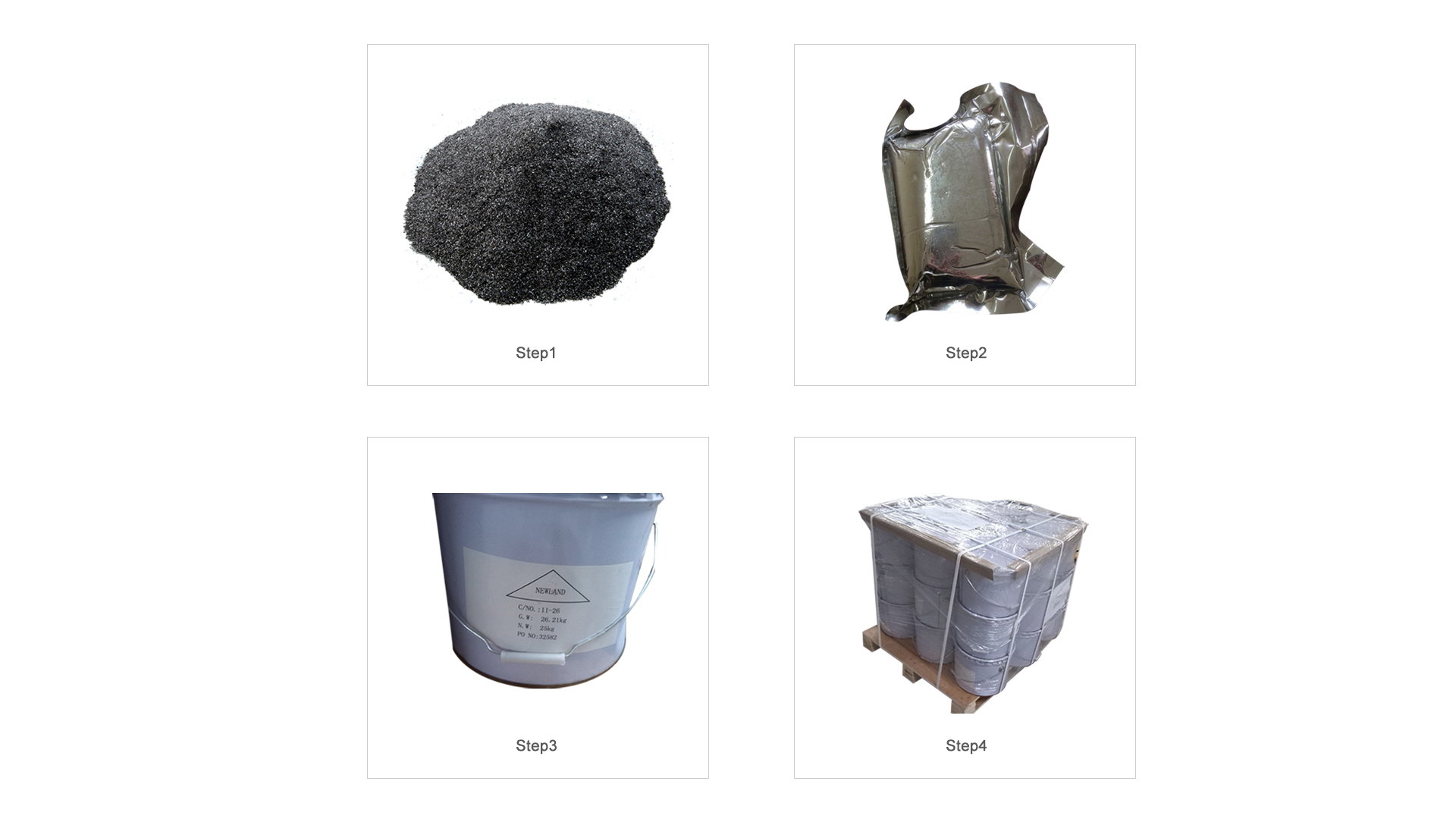

Processing Flow:

1.Jet Casting. Firstly, to melt Neodymium-iron-boron ingot, then jet the metal under high pressure onto the surface of a revolving metal wheel that the wheel is kept at cool temperature while the molten metal is cooled. During the process the material solidifies into a small metal ribbon about 35 µm (micrometers) thick and 1-3 mm wide. By controlling variables such as the flow rate of the metal, the wheels rotating speed, the cooling rate; we can achieve optimum magnetic properties. The gathered ribbon is milled into a platelet and there a heat treatment is carried out to achieve desired magnetic properties.

2.Spinning-cup atomization, much like a centrifuge. Molten metal is ejected into the surface of a rapidly spinning cup and when leaving the rim of the spinning cup, it forms droplets that will form into very small spheres during spinning and solidification. Finally, the powders are collected and heat-treated to achieve desired magnetic properties.

Application:

1.Making isotropic bonded NdFeB magnets, which are manufactured by mixing NdFeB powder with polymer binder and then pressing (compression to form the required shape).

2.The automobile industry: DC brush-type motors. Multi-pole stepper and spindle motor applications.

3.Magnetic paints, magnetic printable substrates, magnetic films, medical diagnostics and therapeutics, video tape, copy toners, fingerprinting, sensors, fuel injectors, permanent magnets, nano level fluid sealing, electric toys and magnetic curing products, etc.