The weight loss of the hot pressed magnetic ring is far less than 1mg/cm2, which has excellent anti weight loss characteristics.

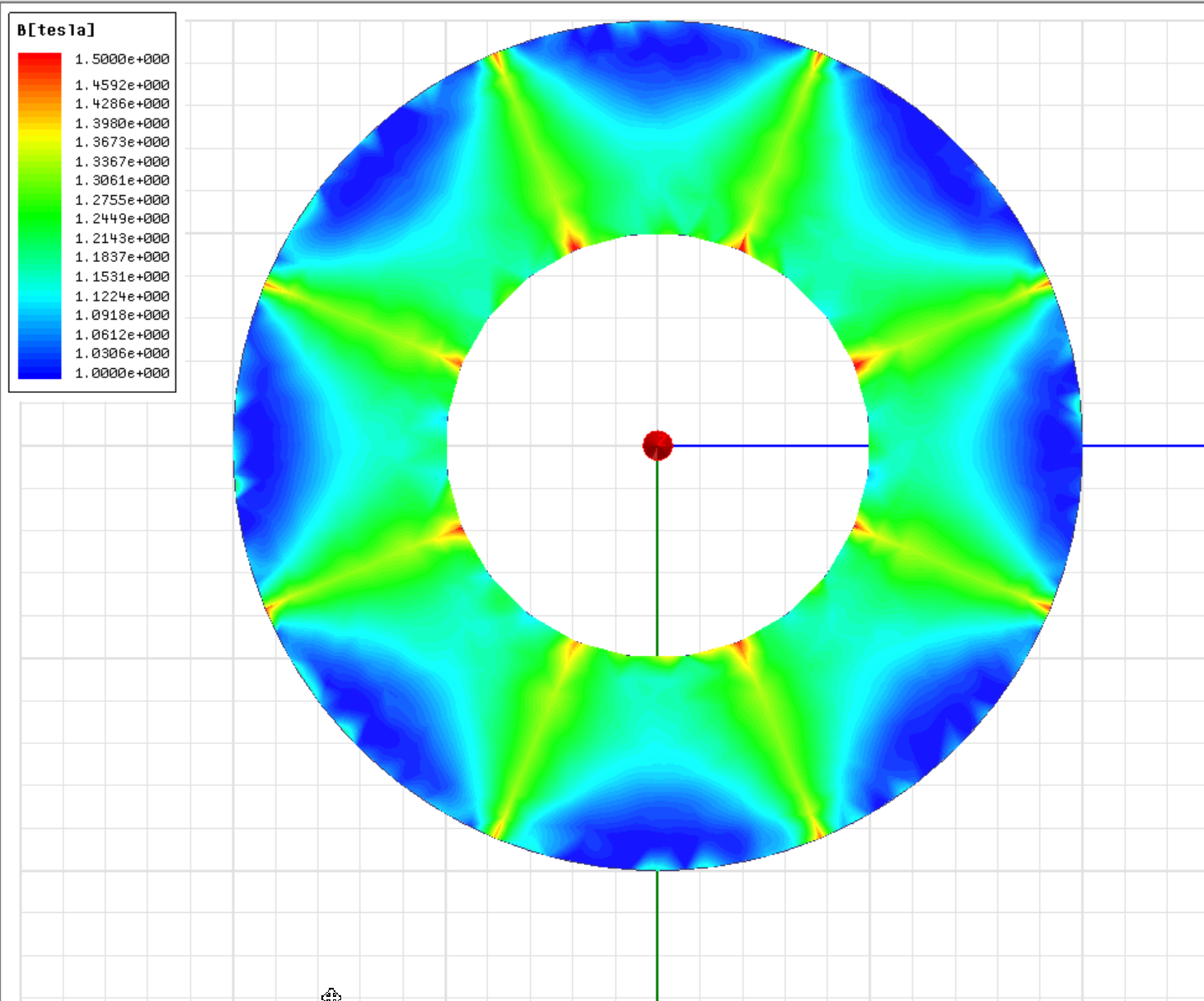

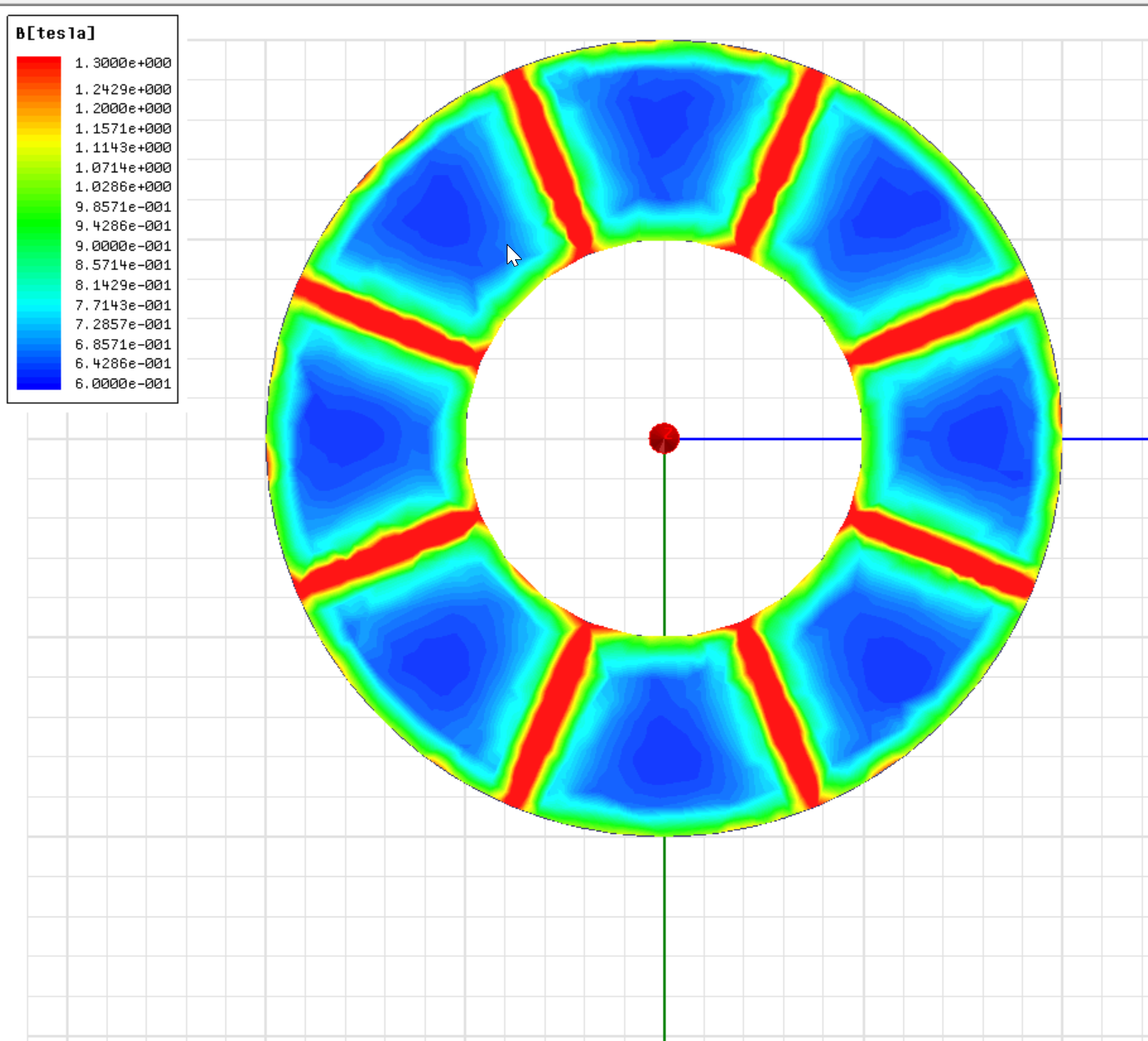

The hot pressed magnetic ring can be prepared into a radiation ring with smaller diameter and higher performance.

Why Choose Hot pressed magnetic ring?

*Chemical Composition: Nd2Fe14B

Neodymium magnets are hard, brittle and easily corrode.

*Moderate Temperature Stability

Neodymium magnets lose -0.09~-0.13% of Br/℃. Their working stability is under 80℃ for low Hcj Neodymium magnets and above 200℃ for high Hcj Neodymium magnets.

*Excellent Strength Value

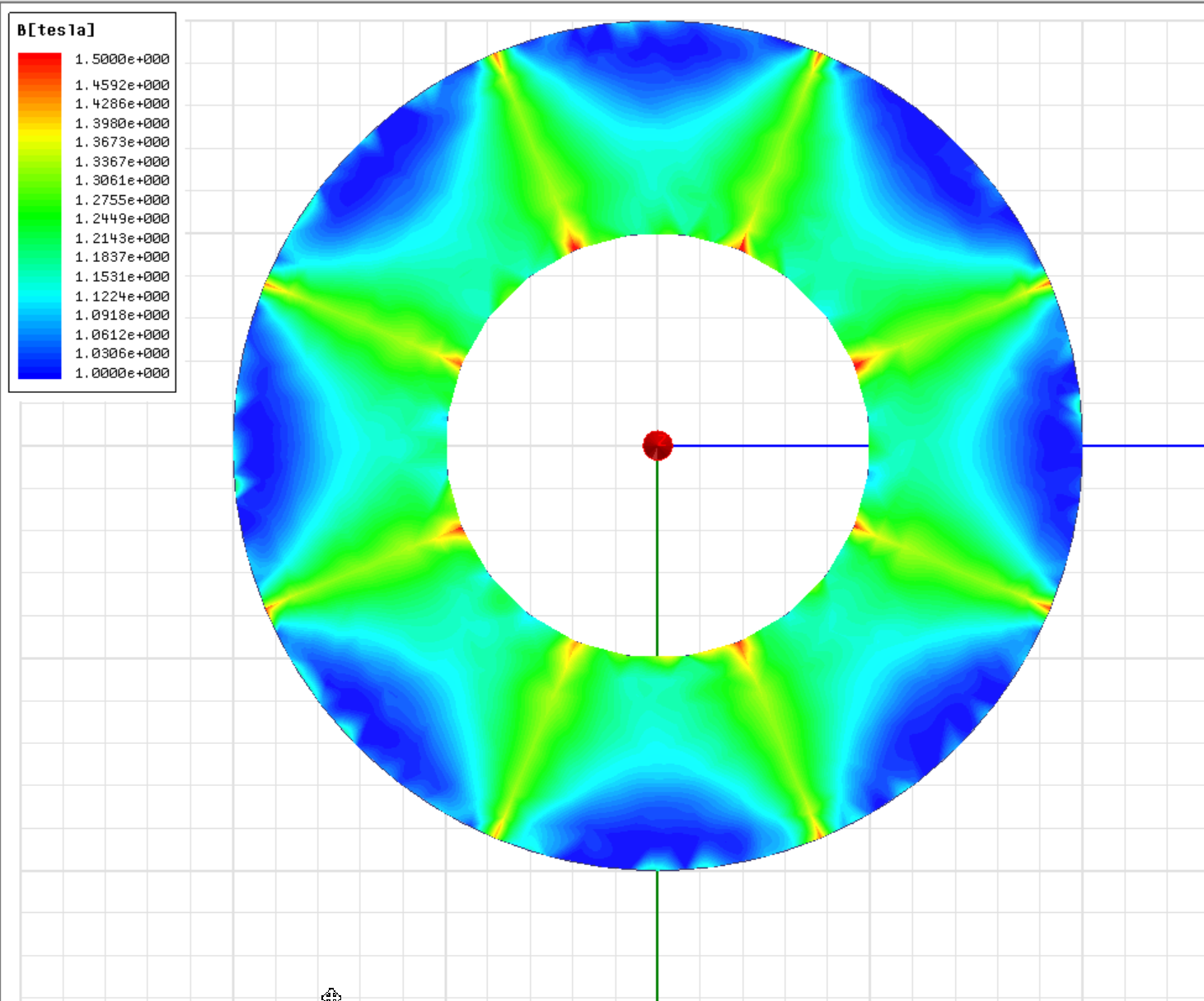

With the decrease of the diameter, the performance of the hot pressed magnetic ring does not decay.

As the diameter of sintered magnetic ring decreases, the orientation magnetic field decays rapidly, so the performance decreases a lot

*Effective Surface Treatment to Prevent Corrosion

Surface treatments have been developed that allow them to be used in most applications. The treatments include gold, nickel, zinc and tin plating and epoxy resin coating.